The switch to sustainable transportation solutions such as electric commercial vehicles is essential for the energy transition and achieving the climate targets in Europe.

One of the main reasons for this: While technical hurdles have largely been overcome, the expansion of the charging infrastructure is stalling, partly due to frozen subsidies, especially in Germany.

Acting progressively

But there is another way, as the Deutsche Verkehrs-Zeitung reports. As an example of progressive action, it cites the logistics service provider TST, which is planning a comprehensive energy supply for e-trucks at its 77 locations together with the energy service provider EWR and the planning office PVSM Energy. They are relying on photovoltaic systems, large storage units and an intelligent infrastructure concept for charging stations. Despite high costs of around 150 million euros, the targets are realistic: 41 systems are expected to generate around 70 gigawatts of electricity by 2025.

Other players such as Milence, the joint electric infrastructure subsidiary of Daimler Truck, the Traton Group and Volvo Trucks, and Ceva Logistics are also working on their own solutions. Ceva Logistics is planning a network of charging terminals along major highways in Europe. Reliable energy supply remains a key problem, especially in view of new energy industry laws that could severely curtail private charging points in the event of grid overload. TST relies on buffer storage and its own energy generation to bridge grid weaknesses.

Continental is driving electrification forward

Continental is also driving electrification forward and, with its EfficientPro and Conti Urban lines, already offers tires that have been specially developed to meet the requirements of electric trucks and buses. These are designed for lower rolling resistance and higher load capacities in order to maximize the range and efficiency of the vehicles. In addition, there are telematics and networking solutions that enable efficient fleet management and control. They support energy management, route planning and maintenance of electric vehicles. For example, fleet managers can use ContiConnect to monitor the condition of the tires in real time, receive problem alerts and plan maintenance to minimize downtime.

Conti Urban – a tire specially developed for the requirements of electric trucks and buses. Photo: Continental

Conti Urban – a tire specially developed for the requirements of electric trucks and buses. Photo: Continental

Continental is also developing electric axle drives that can be integrated into electric trucks. These systems improve efficiency and enable low-noise and emission-free operation. Advanced battery management systems from Continental optimize the performance and service life of the batteries. They monitor and control the battery cells to ensure safe and efficient use.

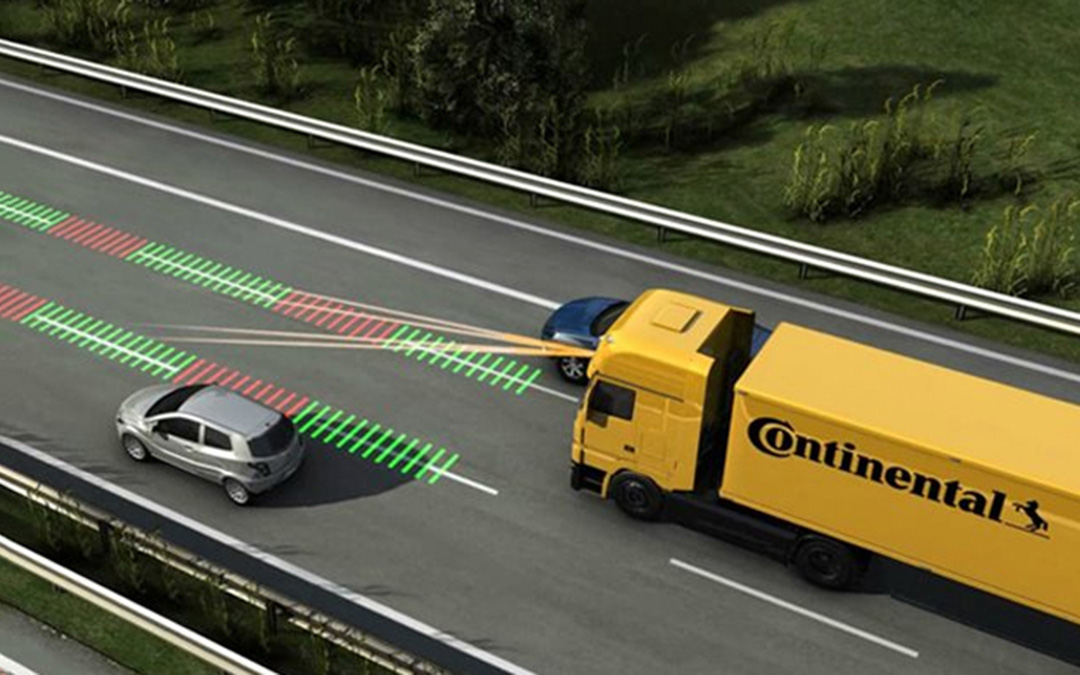

Efficient thermal management solutions are crucial to keep the batteries and other electrical components within the optimum temperature range. Here too, Continental offers systems that ensure temperature regulation for batteries and drives. The premium manufacturer also develops driver assistance and automation systems that make the operation of e-trucks safer and more efficient. These include systems such as automatic braking, lane departure warning and adaptive cruise control.

Continental’s support to keep the line through innovative technologies. Photo: Continental.

Continental’s support to keep the line through innovative technologies. Photo: Continental.

Do you think fleet electrification can be accelerated in the foreseeable future? Tell us what you think!

0 Comments